How T-Shirt Printing impacts event marketing campaigns

Wiki Article

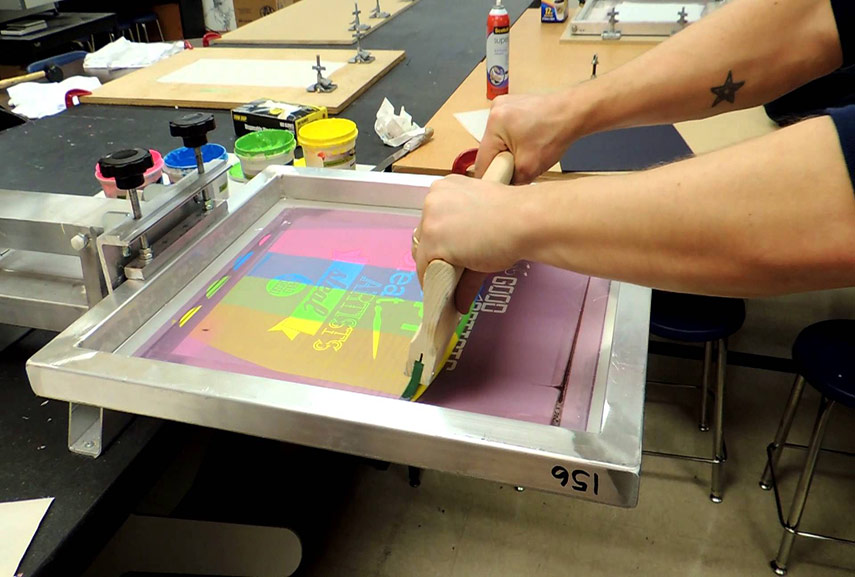

Why T-Shirt Screen Printing Is the very best Choice for Your Next Clothing Task

When thinking about choices for your following clothing job, t-shirt screen printing sticks out as a compelling choice because of its myriad advantages. This method not only supplies a considerable combination of vivid shades that endure the test of time but likewise assures longevity that lots of various other printing techniques can not match. Its cost-effectiveness and adaptability make it ideal for both massive manufacturings and custom designs. There are extra elements that might affect your decision, and recognizing these subtleties might considerably impact the success of your task.Dynamic Color Options

When it pertains to t-shirt screen printing, lively color options play a necessary duty in attracting focus and conveying brand identification. The ability to pick from a wide spectrum of shades allows people and organizations to produce visually striking styles that resonate with their target market. Whether it's a strong logo design or an intricate graphic, the best shade palette can considerably improve the overall appeal of the garments.Screen printing techniques make use of top notch inks that generate abundant, saturated shades, guaranteeing that designs keep their vibrancy even after numerous cleans. This ability is especially crucial for brand names intending to develop a remarkable existence in an open market. By choosing shades that straighten with their brand name worths, companies can properly connect their message and values.

Furthermore, the flexibility of screen printing accommodates numerous color combinations, enabling the creation of eye-catching gradients and effects that can raise a basic layout right into an artwork. The endless possibilities in color option equip designers to experiment and introduce, ensuring that the final product not only satisfies visual assumptions but also stands out in a crowded clothing landscape.

High Durability and Long Life

High resilience and long life are essential advantages of t-shirt screen printing, ensuring that layouts withstand the examination of time and duplicated wear. This printing method uses high-grade inks and robust products that bond successfully with fabric fibers, resulting in prints that resist fading and splitting even after various laundries.Unlike various other printing methods, screen printing develops a thick layer of ink on the garment, enhancing the print's resistance to use and tear. This particular is particularly useful for garments that goes through constant use, such as uniforms, promotional wear, or day-to-day laid-back apparel.

Screen printing enables for the application of specialized inks, such as plastisol or discharge inks, which contribute to the general toughness of the printed style. These inks not only keep their vibrancy with time however also give a soft hand feel, making sure that users stay comfortable while sporting their layouts.

Ultimately, investing in t-shirt screen printing warranties that your layouts will maintain their honesty and look, making it an excellent choice for those seeking long-lasting garments services.

Cost-Effectiveness

How can cost-effectiveness affect your option of t-shirt printing methods? When starting on a garments project, understanding the financial effects of different printing strategies is necessary. Tee shirts evaluate printing stands apart as a specifically affordable option, specifically for bulk orders. The preliminary arrangement prices may be greater because of the production of screens; however, the price each decreases considerably with larger amounts, making it a suitable choice for organizations or businesses aiming to create high volumes.

Moreover, screen printing usually uses sturdy inks that endure multiple washes, offering long-term worth. By investing in a method that yields long-term high quality, you minimize the demand for regular substitutes, inevitably saving cash with time.

Convenience in Style

A plethora of design opportunities makes t-shirt screen printing an exceptionally versatile choice for clothing tasks - Screen Printing. This printing technique fits a variety of colors, enabling vivid graphics that capture focus and convey messages efficiently. Whether you're aiming to produce elaborate designs or strong, straightforward logo designs, screen printing can bring your vision to life with accuracyAmong the standout attributes of screen printing is its adaptability to numerous materials and fabric types. From cotton and polyester to blends, the method guarantees that designs maintain their integrity and top quality no matter the substrate. Furthermore, the capability to print on different garment styles, consisting of tee shirts, hoodies, and storage tank tops, further enhances its flexibility.

Moreover, screen printing supports both small and huge manufacturing runs, making it ideal for personalized projects as well as bulk orders. This versatility in scale allows people, services, and organizations to create one-of-a-kind apparel that meets their specific requirements, whether for marketing functions, events, or personal usage.

Inevitably, the flexibility in design supplied by t-shirt screen printing not only meets varied creative needs yet likewise offers an efficient service for any clothing project.

Eco-Friendly Practices

Integrating eco-friendly methods right into t-shirt screen printing is important for reducing the environmental impact of apparel manufacturing. Utilizing sustainable ink alternatives, carrying out waste decrease techniques, and taking on energy-efficient procedures can greatly improve the sustainability of these tasks. As customers increasingly focus on ecological obligation, adopting these methods not just sustains the planet yet also lines up with market needs.Sustainable Ink Options

Discovering lasting ink options is necessary for environmentally aware screen printing techniques. Conventional inks usually consist of unsafe solvents and chemicals that can negatively affect both the setting and human health. In contrast, sustainable inks, such as soy-based inks and water-based inks, provide eco-friendly options that minimize these risks.Water-based inks are especially notable for their lower levels of unstable organic compounds (VOCs), consequently lowering air pollution during the printing procedure. They are additionally biodegradable, making them a preferable choice for those looking for to decrease their environmental impact. Soy-based inks, originated from renewable energies, not just give vivid shades but likewise assist in less complicated cleaning and disposal compared to petroleum-based inks.

Furthermore, numerous producers are now generating inks that fulfill rigorous ecological standards, guaranteeing that their products are without hazardous materials. Selecting sustainable ink options not just aligns with environmentally friendly values yet also interest customers that prioritize liable manufacturing methods. By opting for these cutting-edge inks, companies can enhance their brand name picture while contributing to a healthier world, making lasting ink alternatives a crucial factor to consider for any type of clothing project.

Waste Reduction Techniques

Executing effective waste decrease methods is vital for promoting eco-friendly techniques in the screen printing industry. By embracing approaches that decrease waste, companies can considerably decrease their ecological impact while maintaining high-quality production criteria.One efficient strategy is to optimize the usage of materials. This can be accomplished by properly calculating the quantity of ink and fabric needed for each and every job, therefore decreasing excess waste. In addition, utilizing ink recycling programs enables the reuse of remaining inks, minimizing disposal and cultivating sustainability.

Another essential strategy is to execute a methodical cleaning process. By employing techniques that record excess ink and other materials during manufacturing, firms can guarantee that these resources are repurposed instead of thrown out. In addition, purchasing electronic printing innovation can decrease waste connected with conventional screen configurations, as electronic methods commonly informative post call for fewer materials.

Energy-Efficient Procedures

Energy-efficient processes play a significant function in enhancing the sustainability of screen printing procedures. By embracing energy-efficient innovations and methods, business can markedly minimize their carbon footprint while keeping high-quality production criteria.Among one of the most efficient techniques is the application of digital printing techniques, which take in less energy compared to typical approaches. In addition, using LED exposure units in the screen-making stage can drastically minimize energy consumption, as they run at reduced temperatures and require much less power.

Maximizing manufacturing timetables and process can contribute to power financial savings. By lessening maker idle time and streamlining procedures, printers can ensure that energy use is focused throughout top production hours. Furthermore, investing in energy-efficient equipment not only decreases power expenses but additionally enhances general functional efficiency

One more environmentally friendly technique includes reusing and reusing materials, which can bring about minimized power consumption in producing brand-new products. By concentrating on energy-efficient procedures, screen printing companies not just add to environmental sustainability yet also produce an one-upmanship in a market that progressively values eco-conscious techniques. Consequently, energy effectiveness is crucial for a thriving and responsible screen printing operation.

Quick Turnaround Times

Accomplishing fast turn-around times in Tees screen printing is essential for satisfying client due dates and assuring consumer satisfaction. The efficiency of the screen printing process enables services to generate high-quality garments rapidly, accommodating urgent requests without compromising on quality.Modern screen printing innovations and strategies have structured manufacturing process, making it possible for operators to carry out several styles and colors in a single run. This capability significantly decreases the time invested in setup and adjustments, resulting in faster completion of orders. In addition, competent employee are trained to optimize each action of the procedure, from art work preparation to printing and curing, which even more enhances efficiency.

Lots of screen printing facilities are equipped to take care of differing order sizes, permitting for the adaptability to focus on urgent tasks. This capability to rapidly adjust to rising and fall needs guarantees that clients receive their items promptly, cultivating depend on and dependability in the solution.

Ideal for Bulk Orders

Tee shirts screen printing is an outstanding option for mass orders because of its affordable production technique, which significantly lowers per-unit costs. This strategy assurances regular quality result across big amounts, making it perfect for businesses or occasions needing consistent apparel. Business Branding Services. As demand for marketing things and team equipment rises, screen printing stands apart as a trusted serviceCost-efficient Production Technique

When it comes to producing clothing in huge quantities, screen printing sticks out as a very affordable manufacturing method. This technique permits considerable savings on both materials and labor, making it a perfect option for services wanting to create bulk orders. The preliminary configuration expense for screen printing may be greater than other printing methods; nonetheless, these prices are promptly countered by the reduced price per unit as production quantity rises.Among the vital benefits of screen printing is its capability to create lively shades and elaborate styles at a lower price contrasted to choices like electronic printing. When the screens are prepared, the printing process ends up being incredibly efficient, enabling high output prices. This effectiveness is especially helpful for companies aiming to fulfill huge orders within limited deadlines.

Additionally, screen printing's resilience guarantees that the layouts stay intact via numerous laundries, minimizing the demand for replacements or reprints. This longevity converts to cost financial savings gradually, additional strengthening screen printing's placement as a financially smart selection for bulk garments production. By leveraging this method, organizations can maximize their budget while providing premium products to their customers.

Constant Top Quality Outcome

Screen printing not only uses an economical service for mass apparel production yet likewise assures consistent high quality result across huge orders. This printing technique uses a stencil-based approach, enabling for consistent application of ink on various material kinds. Consequently, screen printing ensures that each product in a mass order preserves the very same dynamic shades, crisp lines, and overall visual allure.One of the essential benefits of screen printing is its ability to produce high-quality layouts that stay long lasting, even after numerous cleans. This integrity is vital for companies intending to develop a cohesive brand photo, as inconsistency in top quality can lead to client dissatisfaction. Breakthroughs in screen printing modern technology have even more improved the precision of the process, allowing elaborate designs and color gradients without compromising high quality.

Often Asked Inquiries

What Fabric Enters Job Best for Screen Printing?

Can I Print on Dark-Colored Fabrics?

Yes, you can print on dark-colored fabrics using screen printing. However, it normally calls for making use of specialty inks, such as opaque or white inks, to assure that the layout stands out against the textile's background.What Is the Minimum Order Amount for Screen Printing?

The minimum order quantity for screen printing commonly varies from 12 to 24 items, depending upon the printer's policies and the complexity of the style. Higher amounts can usually yield more economical prices per system.Exactly how Do I Look After Screen Printed Wardrobe?

To take care of screen printed garments, clean them inside out in chilly water, avoid bleach, and tumble completely dry on low warmth. Furthermore, refrain from ironing straight on the print to preserve its honesty and appearance.Exist Any Limitations on Layout Information And Facts?

Yes, screen printing has restrictions on design details, specifically with elaborate layouts and gradients. Great lines, small message, and intricate color variants may be testing to reproduce, requiring careful consideration throughout the design procedure.Screen printing techniques use top quality inks that generate rich, saturated shades, making sure that designs preserve their vibrancy also after multiple laundries (Abilene T-Shirt Screen Printing Company). Unlike other printing methods, screen printing develops a thick layer of ink on the garment, improving the print's resistance to tear and wear. Screen printing enables for the application of specialized inks, such as plastisol or discharge inks, which contribute to the total longevity of the printed style. Screen Printing. In comparison, various other printing techniques, such as direct-to-garment (DTG) printing, might be extra appropriate for little runs however usually sustain higher costs per product. One of the vital benefits of screen printing is its ability to produce vibrant shades and complex designs at a reduced cost compared to choices like electronic printing

Report this wiki page